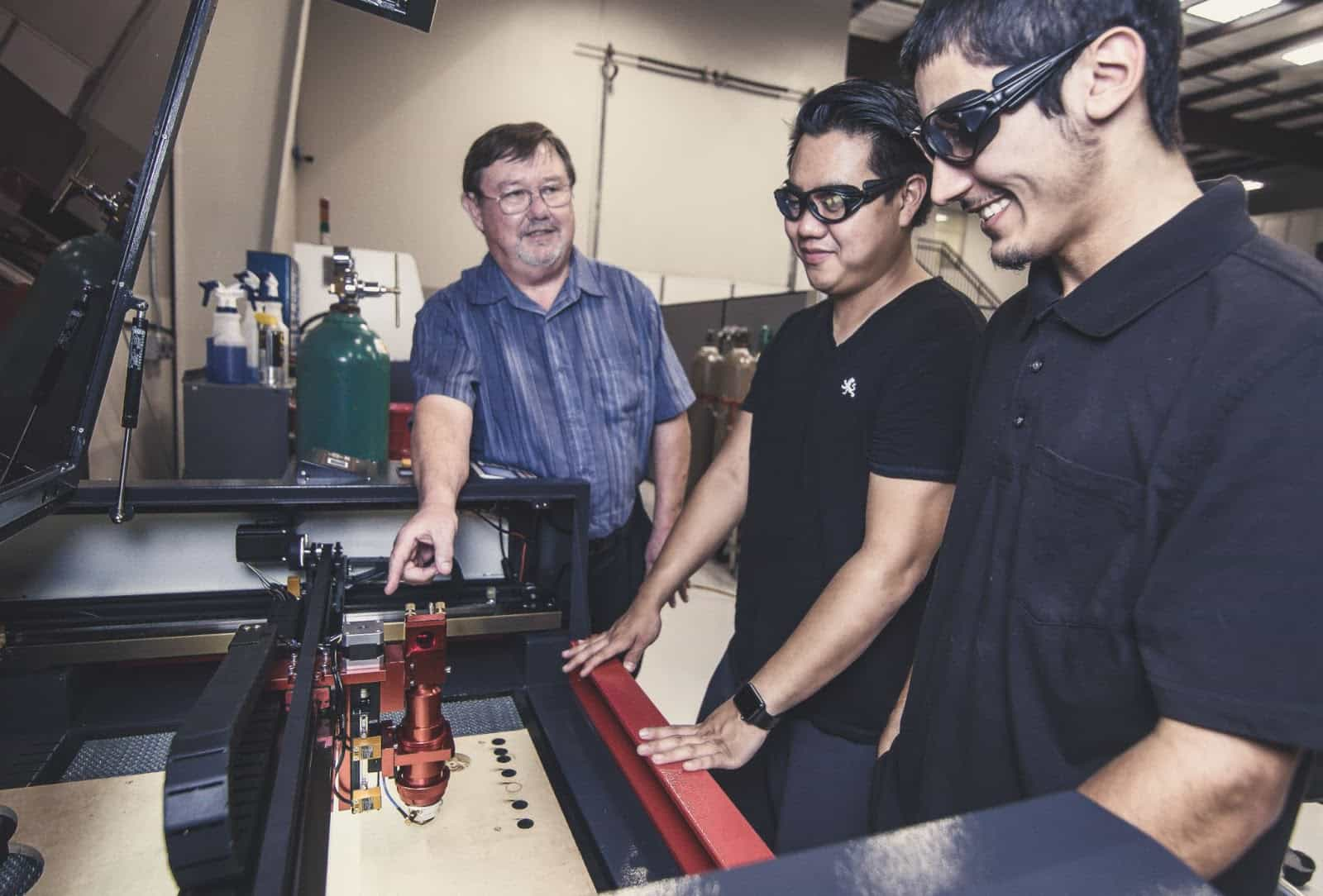

10 Step Fiber Laser Cutting Process

The fiber laser cutting process reliably cuts “fiber laser cut metal” and other materials. Fiber laser cutting is recognized for its precision, speed, and flexibility, making it a good fit for the aerospace, automotive, and metalworking sectors. The method offers several advantages over conventional cutting technologies: better cutting rates, more precision, cheaper cost of operation, … Read more