Laser technology has changed many fields, from medicine and manufacturing to scientific research and communication. Many different kinds of lasers are able to be used for many different things. Each type has its unique properties and traits. Anyone who works with laser technology needs to know about the different kinds of lasers and what they are able to do. It is able to open up many possibilities in fields as different as aerospace engineering, biotechnology, and telecommunications.

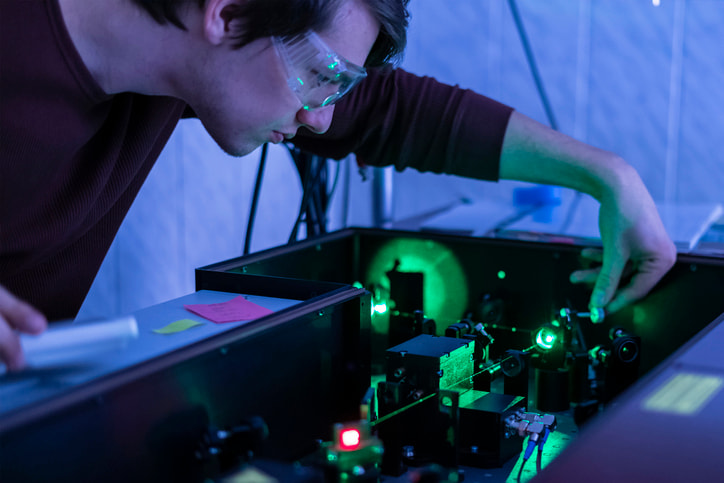

A laser is a device that uses stimulated emission to create a highly concentrated and intense beam of light. A laser’s light is coherent (consisting of waves in phase with each other) and monochromatic (it has a single wavelength). This makes lasers helpful for a variety of applications, such as medical treatments, scientific research, manufacturing, and communications. Yet, the extreme intensity, narrow wavelength, and collimated nature of lasers make them potentially lethal in the wrong hands. Knowing the various kinds of lasers and their attributes is critical for working with laser technology safely and successfully.

Listed below are the different types of lasers.

- Fiber Lasers: Fiber lasers are a form of solid-state laser in which an optical fiber serves as the lasing medium. The fiber is doped with rare-earth ions, such as erbium or ytterbium, which absorb energy and then release light when stimulated by an external light source, such as a diode laser. The light released by the fiber is magnified as it bounces back and forth between the fiber’s two ends, resulting in a highly concentrated and powerful laser beam.

- Semiconductor Lasers (Laser Diodes): A semiconductor laser, commonly referred to as a laser diode, creates a laser beam using a semiconductor substance, such as gallium arsenide. Several industries, such as telecommunications, printing, and medical procedures, employ laser diodes extensively.

- Gas Lasers: Gas lasers are a kind of laser that produces a highly concentrated and intense beam of light by using a gas mixture as the lasing medium. An electrical discharge or other techniques is commonly used to excite the gas mixture, causing the gas molecules to become excited and produce light energy in photons. The photons then stimulate other excited gas molecules to emit more photons, resulting in a cascade of light amplification known as stimulated emission.

The CO2 laser is the most common type of laser used in industry. CO2 lasers generate a high-powered beam of infrared light with a wavelength of 10.6 micrometers by using a gas combination of carbon dioxide, nitrogen, and helium. CO2 lasers are well-known for their high power output, efficiency, and ability to cut and engrave a variety of materials such as metals, plastics, and wood. They’re common in industrial applications, including cutting, welding, drilling, and marking. CO2 lasers are employed in medicine, such as dermatology, ophthalmology, and dentistry. CO2 lasers have become a staple tool in many sectors due to their flexibility, power, and cheap cost.

1. Fiber laser

Fiber optic laser is the primary tool used in laser cutting and is able to perform various machining processes such as marking, welding, drilling, engraving, and cleaning. Currently, fiber lasers are one of the types of machining that offers the highest quality of finish, production speed, and versatility, as it is the only technique that allows cutting countless materials, from the easiest to the most difficult, in an efficient way that other conventional methods are unable to accomplish.

2. Semiconductor laser

The semiconductor laser is a common type of laser in electronic applications. It is small, easy to manufacture, and requires little power. It is able to be used in numerous applications such as barcode readers, DVDs, CD players, electronic measuring tapes, level indicators, industrial sensors, and many others.

The operating principle is very similar to LEDs since the same material is used in their construction: Gallium Arsenide or GaAs.

There are several ways to stimulate the semiconductor material to cause light emission. The most used is to force a strong current in the forward direction to flow through the indicated structure’s PN junction.

The primary difference with standard LED is that operators do not have uncontrolled light emissions. Still, a resonance chamber with mirroring allows the operator to obtain the effect of the inversion of the excited atoms population and, later, the emission controlled by the electrons back to normal energy levels.

One of the significant advantages of semiconductor lasers is that the nature of the material determines the emission wavelength, that is, the color of the light. This means lasers are able to be manufactured with emissions of different colors or wavelengths.

The first types appeared were devices emitting infrared, and the acquisition cost was very high. Over time, beyond cheapness, it was possible to obtain shorter wavelengths by turning to red, which became popular with Laser Pointers.

3. Gas laser

Gas lasers are used in various applications, including holography, spectroscopy, barcode scanning, air pollution measurements, materials processing, and laser surgery.

The most common and cheapest gas laser, the Helium-Neon laser, is usually built to operate at 632.8 nm. It is able to be constructed to produce laser action at 543.5 nm and 1523 nm.

One of the excited levels of Helium at 20.61 eV is very close to the level in Neon at 20.66 eV, so close that upon collision of an atom of helium and neon, energy is able to be transferred from helium to the neon atom.

Helium-Neon lasers are standard in introductory physics labs but are able to be dangerous. A one mW unfocused HeNe laser has a brightness equal to sunlight on a clear day (0.1 watt/cm2) and is too dangerous to stare directly at, according to Garmire,

The Carbon Dioxide gas laser is able to generate a continuous output power of over 10 kilowatts. It is capable of operating high-power pulses. It exhibits laser action at various infrared frequencies but none at visible. Working similarly to the helium-neon laser, it employs an electrical discharge to pump, using a percentage of nitrogen gas as the pumping gas.

The CO2 laser is the most efficient and is able to operate over 30%. This is much more efficient than an ordinary incandescent bulb that produces visible light (about 90% of the filament lamp output is invisible). The carbon dioxide laser has many applications in industry, particularly for welding and cutting.

The argon ion laser is able to be operated as a continuous gas laser at about 25 different visible wavelengths between 408.9 and 686.1 nm but is best known for its more efficient green transitions between 488 nm and 514.5 nm. Operating at much higher powers than the helium-neon gas laser, achieving 30 to 100 watts of continuous power is not uncommon using various transitions. This output is produced in a hot plasma and takes high power, typically 9 to 12 kW, so they are more extensive and expensive.

4. Solid-state laser

The solid-state laser is a laser whose active medium is a crystal or glass doped with ions, thus differentiating itself from the dye laser that uses an organic dye, usually in a liquid solution, as a light amplification medium and from the gas laser, where an electrical discharge is produced through the corresponding gas (for example, helium-neon) to make the coherent light. This solid material, usually sapphire (Al2O3), neodymium, or ytterbium, is doped with ions commonly from the rare-earth group. The most widespread laser in this group is Nd: YAG (neodym ium-doped with yttrium aluminum garnet). The first solid-state laser was the ruby laser, which is still used in some applications. More recently, the titanium-sapphire laser, capable of generating Fento and Penta second pulses, has been widely used for fundamental research in materials sciences.

5. Liquid lasers

Liquid lasers use a liquid organic dye as the gain medium. They are known as dye lasers used in laser medicine, spectroscopy, removing cravings or birthmarks, and separation of isotopes.

One of the advantages of dye lasers is that they are able to generate a much more comprehensive range of wavelengths, making them good candidates as tunable lasers, which means that the wavelength is able to be controlled during operation.

Lasers, in isotope separation, are tuned to specific atomic resonances. They are therefore adjusted to a specific isotope to ionize the atoms, thus rendering them neutral rather than negatively or positively charged. They are, therefore, separated with an electric field, obtaining what is called isotopic separation.

6. Spectra-Physics Lasers

Single-frequency fiber laser is an ultra-low noise laser with a narrow line width of less than 1 kHz. This device emits ultra-low phase noise and relative intensity noise (RIN). The side mode suppression ratio (SMSR) is greater than 55 dB. The high-intensity s fiber lasers are suitable for various environments, ensuring stable output in single longitudinal mode and free of ‘mode-hops’ even with temperature variation, vibration, or impact.

7. Metal vapor lasers

Metal vapor lasers are particular gas lasers capable of generating gain using metal atoms or metal ions, operating at wavelengths ranging from infrared to ultraviolet.

These types of gases are not suitable to work at room temperature; for this reason, it is necessary to implement quartz tubes capable of withstanding higher temperatures in which the evaporation of the used metal is carried out through a sufficiently intense arc discharge. The most important types of metal vapor lasers are Copper Vapor Lasers, Alkali Vapor Lasers, and Helium–cadmium Lasers.

8. Polariton laser

This type of laser is relatively new and efficiently takes advantage of the coherent nature of Bose condensates of exciton-polaritons in semiconductors to achieve an ultra-low threshold laser. This makes achieving a coherent light source with a different working mechanism than conventional laser light sources possible, guaranteeing better energy efficiency.

9. Nuclear-pumped laser

A nuclear pump laser is pumped with fission fragments’ energy. The laser medium is enclosed in a tube lined with uranium-235 and subjected to a high flux of neutrons in a nuclear reactor core. The uranium fission fragments create an excited plasma with an inverse population of energy levels, emitting a laser. Other methods, for example, the He-Ar laser, are able to use the He(n,p)H reaction, the transmutation of helium-3 into a neutron flux, as an energy source or use alpha particle energy.

10. Electron-free laser

The electrons are not bound to anything (with free), and there are no restrictions for the specific energy of the transitions of the atoms or molecules. Thus they are able to emit radiation at any wavelength (depending on the design of the laser and not the properties of the active medium), which makes them valuable instruments for scientific research in physics, chemistry, biology, the development of new materials, and technologies, and have practical applications in medicine and the military industry.

11. Gravity laser

A gravity laser, known as a Gaser, Graser, or Glaser, is a hypothetical device for the stimulated emission of coherent gravitational radiation, or gravitons, in the same way that a standard laser produces coherent electromagnetic radiation.

12. Samarium Laser

Samarium and the rest of the rare earth are used in the carbon arc for film projection, infrared-absorbing glasses, and neutron absorbers in nuclear reactors.

The SmCO5 alloy has been used to build a new magnetic material with the highest known resistance to demagnetization. Additionally, it has been used to dope calcium fluoride crystals for constructing lasers, especially the X-ray laser.

An X-ray laser is a device that emits X-rays that have the characteristics of laser radiation: coherence, high intensity, and little dispersion. It differs from other lasers because its wavelength is 10 and 0.01 nanometers, about 500 times shorter than visible light. That wavelength is the size of the atom. It is able to be used to determine the molecular structure of compounds that it is able to be employed as medications or to investigate the kinetics of biological processes.

What is Laser?

The word Laser originates is the abbreviation for Light Amplification by Stimulated Emission of Radiation. The laser operation is based on stimulated emission, a concept introduced by Einstein in 1917. However, the laser was only developed in 1960, becoming a type of visible electromagnetic radiation whose main characteristics are: monochromatic, coherent, directional, and high intensity.

The laser beam is produced by energizing atoms or molecules in a substance, causing them to release photons in a precise direction. The photons released then inspire more excited atoms or molecules to generate additional photons, increasing the intensity of the light beam.

Several practical uses exist for laser technology, including medical, communications, industry, and scientific research. Lasers are used in surgery to perform accurate incisions and cauterize wounds, in telecommunications to send data over vast distances through optical fibers, and in manufacturing to precisely cut weld and drill materials. Lasers are employed in scientific research to investigate matter’s characteristics and to perform ultra-precise measurements of distance, time, and other physical variables.

What are the different types of Laser Modes?

Listed below are the different types of Laser Modes.

- Continuous Wave (CW) mode: The laser produces a continuous beam of light with a constant intensity in continuous wave (CW) mode.

- Pulsed Mode: The laser operates in pulsed mode, emitting brief bursts of light whose length and spacing are determined by the particular application.

- Quasi-CW mode: The pulses in quasi-CW mode are more prolonged and closer than in pulsed mode, giving the impression that the beam is continuous.

- TEM modes: The laser beam’s form in the transverse direction is described by the transverse electromagnetic (TEM) modes (i.e., perpendicular to the direction of propagation). The most popular TEM modes are higher-order ones, which have more intricate beam forms than TEM00, which has a Gaussian-shaped beam.

- Multimode: The laser produces several light beams in this mode, each with a marginally distinct phase and path.

- Single longitudinal mode: The laser produces an extremely small linewidth in this mode by emitting light at a single, well-defined frequency.

What type of Laser is used in Laser Cutting?

Laser cutting has developed over the years as an alternative to conventional cutting forms. It swiftly established itself as one of the best and most effective manufacturing techniques for components, particularly metals, because of its precision and versatility. There are three main types of lasers used for cutting: Gas Laser, Crystal Laser, and Fiber Laser.

Gas laser cutting, better known as CO2 laser cutting, is completed using a mixed carbon dioxide laser and electrically stimulating said mixture. Gas laser cutting was not strong enough to cut through metal when it was introduced in 1964. Technology has progressed since then to the point that metals are able to be cut. However, it is best suited for non-metals. The gas laser has an average wavelength of 10.6 micrometers and is employed in a variety of medicinal and industrial settings. Gas laser cutting uses nitrogen, which works well with metals such as steel and aluminum, although care needs to be taken to ensure the nitrogen is pure. Failure to do so is able to oxidize the metal

Crystal laser cutting is a type of laser cutting, which is a process that uses lasers made of Nd-YAG (neodymium-doped yttrium aluminum garnet) and Nd-YVO (neodymium-doped yttrium ortho-vanadate). These crystals are part of the solid-state group, allowing extremely high-power cutting to be used with metals and non-metals. Crystal laser-based cutting has roots that date back to 1964, created in the same labs as gas lasers; Bell Labs. With a wavelength of 1064 micrometers, it is helpful for various applications, from medicine and dentistry to military and manufacturing. The most significant disadvantage of a crystal laser machine is that it is an expensive piece of kit made up of expensive pump diodes. A crystal laser machine has a shorter life expectancy than other machines on the market, around 8,000 to 15,000 hours, which means it is able to cost more over a more extended period, not to mention if expensive pump diodes need to be replaced if they break.

Fiber laser has several similarities with the crystal process in that optical fiber belongs to the solid state group and has a wavelength of 1.064 micrometers. A fiber laser’s most significant benefit is that it has a much longer lifespan than the previous two types of cutting, clocking in at around 25,000 hours, in addition to being the most effective and precise cut in metallic elements, such as carbon steel, stainless steel, aluminum, and even titanium.

What type of Laser is used in Eye Surgery?

Refractive surgery aims to eliminate refractive errors: myopia, hyperopia, and astigmatism.

The surgery consists of the emission of a laser beam that wears down the cornea’s surface, modeling it so that it has a more precise outline. There are three surgical techniques, two of which are the most used, such as PRK and Lasik. The newest is the personalized technique.

The PRK procedure begins with scraping the cornea’s outermost layer, the epithelium, followed by the application of the laser.

A microkeratome is used in LASIK to open a lid on the cornea (a flap) that stays connected at one end. The flap is retracted, and the laser is used to simulate the cornea.

The femtosecond laser is utilized in customized surgery. Corneal wear is accomplished without scraping the corneal epithelium in PRK or raising a flap in LASIK. The laser penetrates the cornea’s stroma layer, modeling its structure without damaging its surface. This eliminates post-operative pain and allows for a speedier recovery.

What type of Laser is used in Hair Removal?

The principle of laser hair removal is as follows: take the laser target and selectively destroy the bulb area without destroying other skin cells. The laser beam follows the hair thanks to its color (melamine that colors the hair shaft) and descends into the hair follicle to destroy the bulb and, therefore, the hair by heating (approximately 60°). This destruction is selective of hairs and is not harmful to the skin.

Permanent laser hair removal, therefore, involves heating to destroy the hair’s germ cells and thus prevent regrowth. It is commonly used light energy from the laser beam. This light is absorbed by melanin (the pigment that colors hair), which is flooded the bulb, and the anagen phase matrix of the hair, which is in the growth phase.

There are two main types of hair removal lasers: Alexandrite laser with 755nm (light phototypes) light and NdYag laser with 1064nm (darker phototypes), based on the specific phototype.

What is the most popular type of Laser?

It must be noted that the most popular laser is the one that has most deeply penetrated society as a whole and not just a particular group. This is true despite the large variety of laser devices currently available and widely used in various applications, including hair and body beauty treatments, cutting and engraving of solid materials, and information transmission, among others. The laser pointer is now the most popular and widely used form of laser in this context because of its vast range of applications in both professional and recreational activities for children, adults, and young people.

Are Lasers dangerous?

Yes, the laser is dangerous if not used properly. Laser light is able to be dangerous for several reasons, including intensity, wavelength, collimation, coherence, and pulse duration. The level of the hazard is determined by many elements, including the strength, duration, wavelength, and mode of the laser beam, as well as the sensitivity of the substance or tissue with which it interacts. Some potential hazards associated with lasers are eye damage, skin damage, fire hazard, electrical hazard, and chemical hazard.

Laser operators must follow acceptable safety protocols and utilize suitable personal protection equipment to limit these threats, laser safety goggles, or shields. Ensuring that the laser is appropriately maintained, calibrated, and used only by qualified and authorized persons is critical.