Our Latest Posts

6 Best Wood Laser Cutters and Engravers

Cutting or engraving wood with a laser cutter offers many advantages: It is very precise, fast, and reliable and is able to be used for small batches or delicate designs. Therefore, laser cutting or engraving of wood pieces is attractive for craftsmen, artists, designers, and DIY enthusiasts. Listed below are the six best wood laser cutters and engravers. 1. ATOMSTACK A5 PRO Laser Engraver The ATOMSTACK A5 PRO is a laser engraver with 40 watts of output power with a very small focus point (only 0.23 mm in diameter). It makes the A5 PRO a very accurate laser engraver. It consists of a full-metal structure and has very precise scaling lines that help to cut as accurately as possible. The focus is entirely fixed, which makes it much easier to adjust to every engraving need. The A5 PRO is able to cut wood plates up to 12 mm thick and

Laser: Definition, History, How It Works and Laser Technology

Lasers, which stand for Light Amplification by Stimulated Emission of Radiation, are machinery that uses stimulated emission to create a coherent light beam. A focused, monochromatic, and directed type of light known as a laser beam has a wide range of uses in research, health, business, and daily life. The basic concept for the stimulated emission of radiation was initially put forward by Albert Einstein at the beginning of the 20th century, which is when lasers first became popular. The first functioning laser was created in 1960 by Theodore Maiman as a result of years of study on the subject by scientists all around the globe. Lasers have now evolved into crucial tools in a variety of industries, including communication, industry, medicine, and scientific research. Rapid advancements in laser technology have led to the creation of several kinds of lasers, including gas lasers, solid-state lasers, diode lasers, and fiber lasers.

12 Different Types of Laser

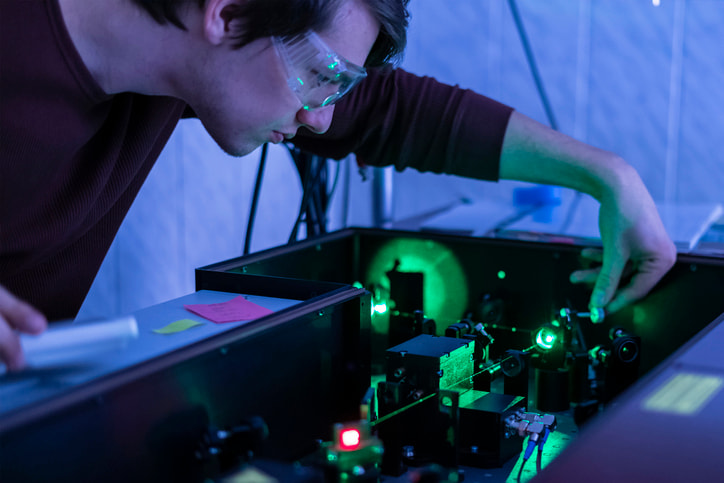

Laser technology has changed many fields, from medicine and manufacturing to scientific research and communication. Many different kinds of lasers are able to be used for many different things. Each type has its unique properties and traits. Anyone who works with laser technology needs to know about the different kinds of lasers and what they are able to do. It is able to open up many possibilities in fields as different as aerospace engineering, biotechnology, and telecommunications. A laser is a device that uses stimulated emission to create a highly concentrated and intense beam of light. A laser’s light is coherent (consisting of waves in phase with each other) and monochromatic (it has a single wavelength). This makes lasers helpful for a variety of applications, such as medical treatments, scientific research, manufacturing, and communications. Yet, the extreme intensity, narrow wavelength, and collimated nature of lasers make them potentially lethal in

How to Laser Engrave and Cut Mylar (Extruded)

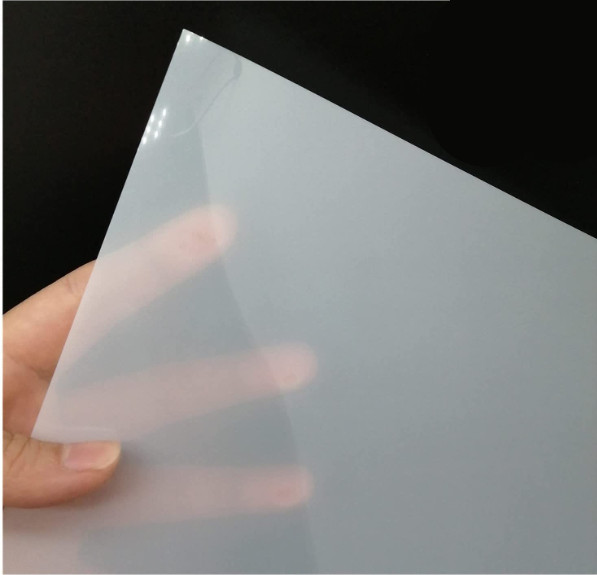

Mylar is the brand name of the DuPont Company. It describes a specific type of extruded polyethylene terephthalate (PET). It usually comes in the form of transparent sheets with some micrometer thickness. It is an excellent electrical insulator with high tensile strength and chemical stability. Mylar often comprises thin foils; hence, less laser power is required. Twenty to thirty Watts must be plenty for cutting, even at fast speeds. However, it is able to create some fumes and smoke. Thus, good ventilation or sufficient airflow must be used. A low-power system like a CO2 laser is an excellent choice for cutting Mylar stencils. Engraving Mylar with a laser is not common, but it is able to be done. It is essential to choose relatively thin plates of Mylar. It twists and releases bubbles if the sheet is too thick. The maximum thickness must be 1.6 mm. Below are the steps

The Difference Between Nd:YAG and Nd:YVO4 Lasers

Nd:YAG and Nd:YVO4 are both solid-state lasers, meaning they both use a crystal as the laser-active material. In the case of Nd:YAG, it is a neodymium-doped yttrium aluminum garnet. This means the YAG crystal has neodymium atoms added to its crystal structure. In contrast, the Nd:YVO4 laser has neodymium atoms built into a yttrium orthovanadate (YVO4) crystal. These two lasers emit infrared light with a wavelength of 1.064 nm, thus creating nearly identical laser beams. Both types are diode-pumped solid-state (DPSS) lasers, meaning the laser light is generated by pumping a solid crystal with a laser diode. The laser diode, a light-emitting semiconductor similar to an LED, acts as a seed light source for the DPSS when an electrical current passes through it. DPSS lasers offer many advantages, the most important being their high efficiency and the ability to be built in small sizes. Nd:YAG has an efficiency of up

Plasma Cutting: Definition, How it works, History, Types, and Components

What is Plasma? Plasma is an ionized gas that reacts to electric and magnetic fields. Unlike everyday gas, which consists of atoms or molecules, the electrons in plasma are stripped away, allowing them to move freely. This also holds true for the ions, the remains of atoms or molecules. Plasma is an excellent electrical conductor as both electrons and ions carry electrical charges. The term plasma was coined in the 1920s by physicist Irving Langmuir and is derived from Greek, meaning ‘something to be molded.’ Plasma can be created in various ways, such as using radio frequency, microwaves, or high voltages to ionize a gas. Its unique chemical and physical properties make plasma suitable for a wide range of technological applications. Plasma naturally occurs in stars, lightning, and the aurora borealis. Plasma can reach temperatures of several thousand Kelvin, making it viable for cutting metal sheets up to 150 mm

Oxidation Melting Cutting: Definition, How it Works, Uses, and Benefits

Oxidation melting cutting is one of the most popular metal-cutting methods. It is relatively simple and inexpensive and has numerous advantages. It offers a precise and tailored cut. It is able to be done manually or machined by portable or large machines. It is able to be defined as “a process of sectioning metals by localized and continuous combustion due to the action of a jet of high purity O2, acting on a point previously heated by an oxy-fuel flame”. Cutting materials is one of the most critical steps in the steel chain. The finished plates must be cut into pieces for their final destination, and the scraps must be cut into smaller pieces to facilitate their subsequent processing. The cuts are able to be divided by mechanics, by melting the metal, combining fusion and vaporization, and by chemical reaction. The process typically involves six steps: material preparation, a laser

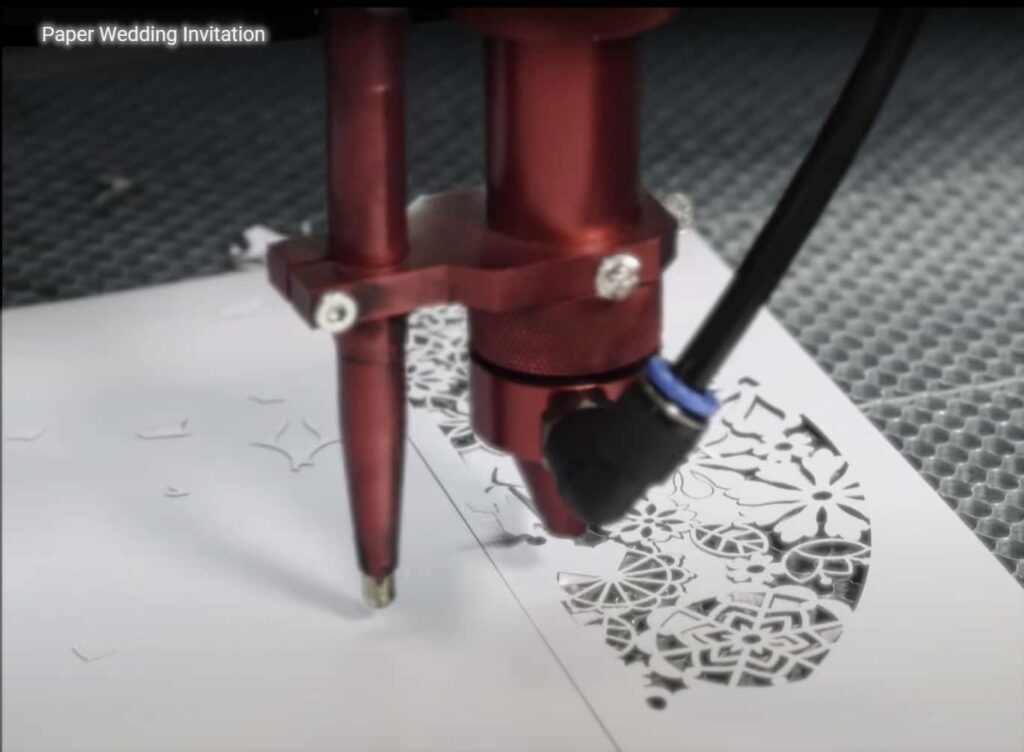

How to Laser Cut Paper?

Laser cutting is a method of cutting or etching materials with a powerful laser. A laser cutter is able to cut elaborate patterns and forms with exceptional accuracy in the context of paper by directing a laser beam at the paper and burning away the material along a predetermined route. On the other hand, laser engraving uses the same technology to etch designs or patterns onto the surface of the paper without cutting all the way through. It gives the paper a decorative look, with the depth of the engraving depending on how intense the laser beam is. There are a number of laser cutters that is able to be used efficiently for paper laser cutting. CO2 laser cutters are the most prevalent form of the paper laser cutter. They give exceptional accuracy and control over the cutting process, making them suitable for complicated patterns and forms. CO2 lasers employ

8 Best Types of Paper for Laser Cutting

Paper, in all its varieties, is a superior material for laser cutting and engraving. It is able to be cut or engraved easily and with high speed and precision. A laser cutter is able to be utilized to create all kinds of customized paper items. Some examples are postcards, business cards, paper artwork, or book covers. Listed below are the best types of Paper for Laser-cutting. 1. Cardboard Cardboard is a particular type of paper or working material. It is able to be produced from recycled paper, sawdust, or cellulose. It is much stiffer than usual paper and is used for different types of packaging, not only egg cartons but for playing cards or tubes for toilet paper and kitchen tissue. Different types of cardboard include containerboard, corrugated fiberboard, or bleached and unbleached board. Containerboard is used to make packaging containers and corrugated fiberboard, which consists of a corrugated layer

How to Laser Engrave and Cut Polyimide (Extruded and Cast)

A 355 nm laser system is the best tool for engraving or cutting polyimide (PI or Kapton) with a laser. The most prominent type for this wavelength is an Nd: YAG laser. It combines high accuracy with fast cutting or engraving capabilities. A powerful laser beam is directed upon the substance in both circumstances. It leads to the evaporation or melting of the PI. The result is going to be highly precise cutting edges and good reproducibility. The optimum power, speed, focal length, and airflow level are strongly dependent on the thickness of the Kapton plate that must be cut or engraved. The rule of thumb is: The thicker the plate, the higher the laser power and the lower the speed. Listed below are the five steps on how to Laser Engrave and Cut Polyimide (Extruded and Cast) How to Laser Cut and Engrave Extruded Polyimide? Listed below are the