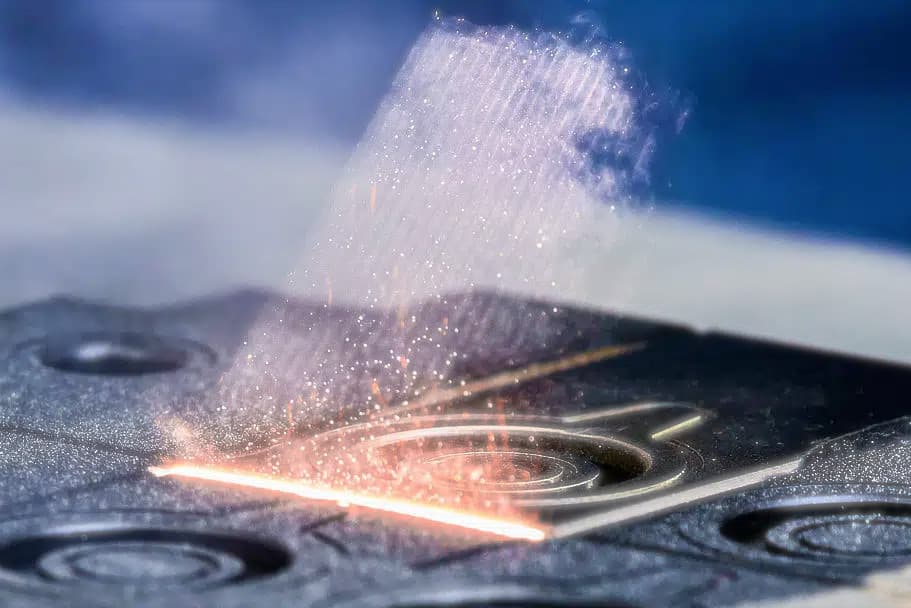

Laser Vaporization Cutting is a special form of laser cutting. It is a particular technology that uses a very strong laser beam that hits the surface of the workpiece. The laser beam rapidly heats the top surface layer. The material evaporates as the temperature rises over its boiling point. The laser beam’s high energy allows evaporation before the substance melts. Laser vaporization cutting is mostly used for thin plates of metal, paper, wood, or plastic.

Moreover, laser vaporization and laser fusion cutting are similar processes. However, they are not exactly the same. Laser vaporization, or laser ablation, is often used for tasks such as micromachining, cleaning the surface, and laser drilling.

On the other hand, laser fusion cutting is the process where the laser beam is pointed directly at the material, which quickly heats up and melts. A high-pressure gas jet blows the melting material away, creating a clean incision. The method is often used in the manufacturing industry to cut and shape metals, such as stainless steel, aluminum, and titanium.

Both processes use a high-energy laser beam to remove material from a solid surface, but there are differences in how the material is removed. Laser vaporization gets rid of things by turning them into vapor, while laser fusion cutting melts things and blows them away.

What is Laser Vaporization Cutting?

Laser vaporization cutting, which is called laser ablation cutting, is a way to remove material from a solid surface by turning it into vapor. An intense laser beam is aimed at the surface of the material when laser vaporization cutting is performed. The laser beam has very high energy, which rapidly heats the material surface beyond the boiling point. It leads to the immediate vaporization of the workpiece material. The laser beam precisely cuts through the whole plate after a certain time.

Usually, laser vaporization cutting is applied for thin plates of metal, wood, or plastic only. However, thicker plates are able to cut as well, but the minimum laser beam power density must be more than 110 W/cm².

Laser vaporization cutting is important because of its precision, speed, versatility, minimal heat-affected zone, cost-effectiveness, and clean and environmentally friendly.

Laser vaporization cutting has to be done in a vacuum chamber because the pressure around it needs to be as low as possible for a fast and reliable result. It is the most prominent downside of the method because the requirements are larger for a vacuum system than for a conventional laser cutter. On the other hand, the benefit is that there is no melting of the material during the laser cutting process, which makes cutting edges much smoother.

How effective is Laser Vaporization Cutting?

Laser vaporization cutting is very effective, and yields clean cutting edges. The effectiveness of laser vaporization cutting depends on several things, such as the type of laser system used, the power and energy density of the laser beam, and the material being cut. Generally, laser vaporization cutting is a very precise, fast, and efficient way to cut through a wide range of materials. However, the working piece has to be put into a vacuum environment. The vapors have to be pumped out of the chamber. The big advantage of laser vaporization cutting is that there is only a little or no melting occurring on the edges. Therefore, the technology is often applied in industries that need high-precision cuts and sharp cutting edges. Prominent examples are the automotive industry, toolmaking, and aerospace companies. It has to be kept in mind, though, that laser vaporization cutting is best suited for cutting thin plates. Other techniques must be considered for thicker workpieces.

Is Laser Vaporization Cutting Safe to Use?

Yes, laser vaporization cutting is safe to use, provided that the usual safety measurements are applied. For instance, safety glasses must be used, or the laser cutter must be enclosed. It is necessary to have a pumping system that is able to get rid of all the vapors or fumes that are produced during the cutting process.

What are the Advantages of Laser Vaporization Cutting?

Listed below are the advantages of Laser Vaporization Cutting.

- Laser vaporization cutting is a highly speedy and precise method of cutting, similar to the other laser cutting methods.

- Small batches of stencils, etc., are able to be produced at a low cost.

- There is no oxidation of the cutting edges during laser vaporization cutting since the process is carried out in a vacuum.

- There is nearly no melting of the cutting material. Thus, the cutting edges are able to be sharp without any bulges on top.

- One is able to cut through materials for surgery or piercings like titanium easily and hardened stainless steel, as well as gold and silver. Here again, sharp edges are very important. Thus, no bulges on the cutting edges avoid additional post-cutting treatment like smoothening or polishing.

- Laser vaporization cutting is a very advantageous method to carve out even complex shapes with high speed and precision.

What are the Disadvantages of Laser Vaporization Cutting?

Listed below are the disadvantages of Laser Vaporization Cutting.

- Vacuum equipment is needed. A lot of vapor is created from the workpiece material during the cutting process. The gas has to be pumped out of the vacuum chamber. Thus, the laser cutter setup is more complex and costly than ordinary cutting machines.

- Some materials release chemically aggressive or even poisonous fumes and vapors. Those have to be handled with care. It must be avoided that these fumes reach the vacuum pump as they are able to damage it heavily.

- There are limitations to the material thickness that it is able to cut. The laser beam has to heat the material above the boiling point in an extremely short time. It requires very high laser power densities, which are above 110 W/cm². The laser power is going to be insufficient to vaporize the substance once it reaches a particular thickness effectively.

What are the Materials that can be used in Laser Vaporization Cutting?

The most popular materials for this cutting method are paper and thin plates (or foils) of metal or plastic because laser vaporization cutting produces the best results with thin plates.

Metal plates have the highest effectiveness because, usually, their vapors are easy to get out of the system. They have good thermal conductivity, which means that the heat transfer inside the material is very rapid. The cuts become exceedingly accurate since the heat rapidly dissipates close to the laser focus. The edges are sharp and neat as well.

Plastics are able to be cut with laser vaporization very effectively. However, it has to be noted that some plastics are able to create toxic fumes that have to be filtered out before they reach the exhaust of the vacuum pump.

Paper, by nature, comes in thin sheets that are able to be easily cut with a vaporization laser cutter. Therefore, the laser cutting procedure is able to be done very rapidly as well. The paper cutting edges remain blackened, though, because the paper is going to be burned a little bit by the laser beam.

Overall, laser cutting is a flexible cutting process that may be used to precisely and accurately cut a broad variety of materials. The laser and cutting process utilized are going to be determined by the materials used for laser cutting and the desired cutting results.

What is the Best Laser Vaporization Cutting Machine?

The best laser vaporization cutting machine is determined by the application and materials being cut. Many machines have various capabilities, such as power, energy density, wavelength, and pulse duration, that are tailored for certain materials and thicknesses.

Theoretically, a vaporization laser cutter is able to be made from every laser with a power density high enough, which is more than 11 W/cm2. There are plenty of suitable machines out there.

First, The FC-6012 Elite Fiber Laser Cutting Machine from Boss Lasers. It is a fiber laser cutting machine made by Boss Lasers, which makes laser cutting and engraving machines as its main business. The FC-6012 Elite is made for industrial use and is able to cut a wide range of materials, including metals, plastics, and composites. It has various key features. The machine has a 1000W fiber laser that gives off a lot of energy, so it cuts quickly and precisely. Its cutting area is 6′ x 12′, so it cuts large sheets or a number of smaller ones in one pass.

Moreover, it has an automatic focusing system that changes the length of the laser beam’s focal point in real-time. It makes sure that the cutting quality is the same all over the workpiece. It uses a high-precision servo motor system and a ball screw drive system to control motion precisely and smoothly. Furthermore, the machine comes with software that is easy to use and lets the operator program and control the cutting process with ease.

The cost of the Boss Lasers FC-6012 Elite fiber laser cutting machine varies based on the configuration and features chosen. Generally, the machine’s basic pricing begins at about $90,000 USD. Nevertheless, if additional features are added, such as a higher wattage laser, an automated loading and unloading system, or a rotating axis for cutting cylindrical items, the price might skyrocket.

Second, the DX-1325 is a fiber laser cutting device made by DXTECH, a company that makes laser engraving and cutting equipment. A variety of materials, including metals, polymers, and composites, are able to be cut with the DX-1325, which is intended for industrial application. It has myriad key features. The device has a 500W or 1000W fiber laser that produces high energy density for fast and accurate cutting. The machine’s 4′ x 8′ (1325) cutting area enables the cutting of big sheets as well as many smaller sheets in a single pass.

Additionally, the machine is equipped with an automated focusing mechanism that instantly changes the laser’s focal length to guarantee uniform cutting quality across the whole workpiece. Accurate and smooth motion control is provided by the machine’s high-precision servo motor system and ball screw drive system. Accurate and smooth motion control is provided by the machine’s high-precision servo motor system and ball screw drive system.

The cost of the DX-1325 fiber laser cutting machine is able to change based on things like the power of the laser, how it is set up, and any extra options or accessories chosen. Usually, the base price of the machine starts at around $35,000 USD for a 500W laser and is able to go up to $50,000 USD for a 1000W laser with extra options.

Lastly, the G. Weike LF6025GAR is one of the best laser cutting machine. It is a high-precision fiber laser-cutting machine manufactured by G. Weike, a Chinese laser-cutting and engraving equipment maker. It is intended for industrial application and can cut a wide range of materials, including metals, plastics, and composites. It has numerous key features. The apparatus has a 1500W or 2000W fiber laser with high energy density for fast and accurate cutting. It is equipped with an automated focusing mechanism that instantly changes the laser’s focal length to guarantee uniform cutting quality across the whole workpiece.

Moreover, the machine’s 2500mm x 6000mm cutting surface enables it to cut large sheets as well as many smaller sheets in a single run. Smooth and precise motion control is achieved by the machine’s use of a high-precision servo motor system in conjunction with a ball screw drive system. Powerful software is included with the machine, making it simple to design and manage the cutting process, including automated nesting and cutting route optimization.

The cost of the G. Weike LF6025GAR fiber laser cutting machine depends on various aspects, including the laser’s power, the exact setup, and any extra options or accessories selected. In general, the machine’s basic price begins at $200,000 USD for a 1500W laser and may rise to $300,000 USD for a 2000W laser with extra options.

What makes laser vaporization cutting different from other types of cutting?

The most prominent difference between laser vaporization cutting and traditional cutting methods is the speed, reliability, and precision. There is no fraying of the cutting edges. The cuts are clean and sharp. Laser cutters enable the manufacturing of small batches at a reasonable cost. They are very flexible as well. One only needs the desired cutting shape in a suitable computer file. Any form or shape is able to be cut without changing the hardware itself.

Can Laser Vaporization Cutting only make holes in Materials?

No, laser vaporization cutting can do much more than punching holes into plates. It is able to cut delicate shapes with high speed and superior accuracy. The results are able to be easily reproduced, and the same machine cuts various materials as long as the plates are not too thick. One is able to produce extravagant designs, stencils, artworks, or mechanical parts. The cutting edges are sharp and well-defined. A laser not only vaporization cutter is well-suited for paper, plastics, or metal but also for rubber, cork, or fabric.